Biotech Production Process – Sacco System

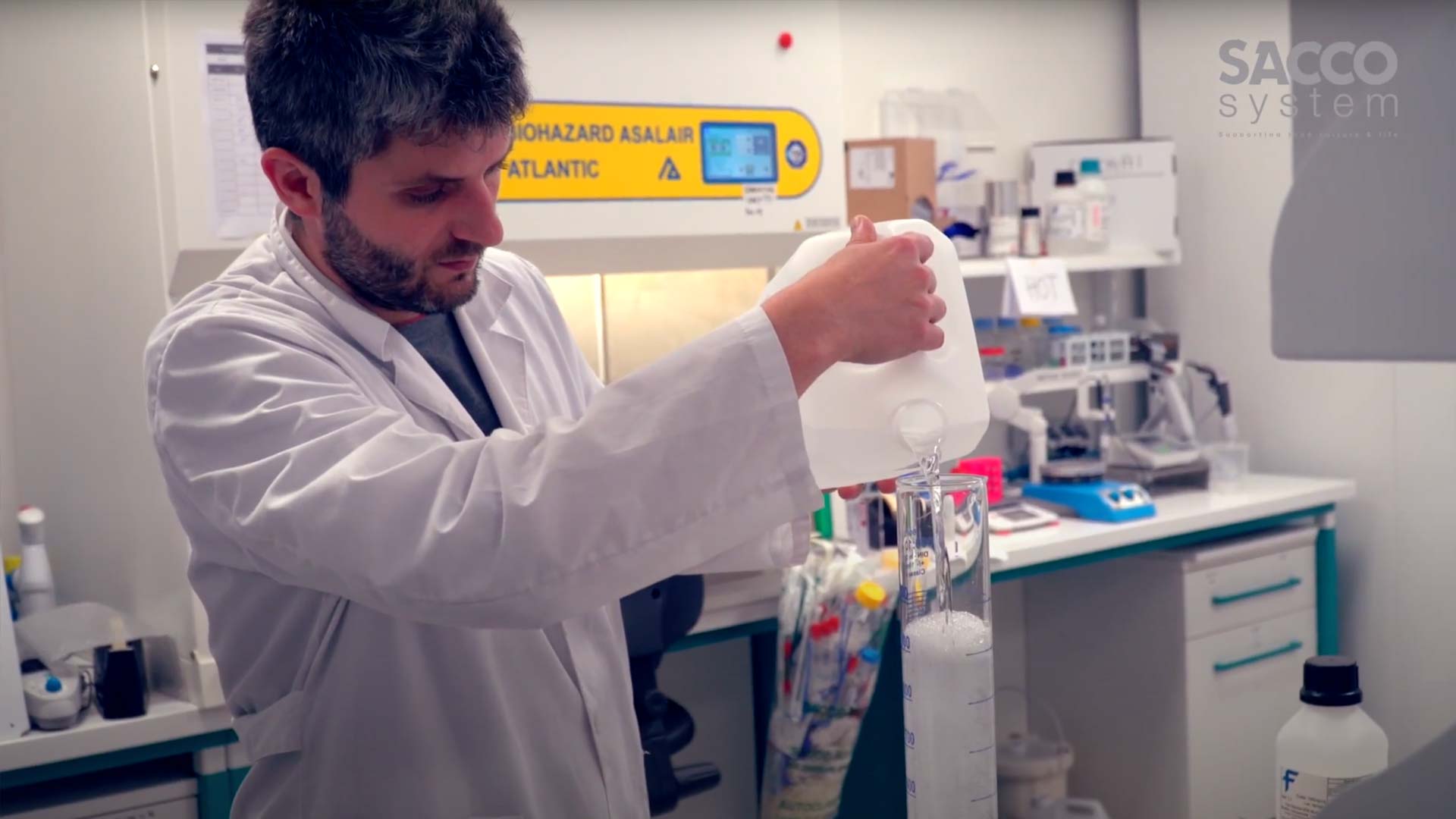

The Industrial manufacturing of probiotics.

Science and technology provide a comprehensive set of useful tools to tackle many challenges encountered during the development of the industrial manufacturing of probiotics.

The development of the fermentation is not limited to the choice of media formulation to guarantee best yields but starts with the strategic sourcing of raw materials that comply with international regulations, continues with a proper design of process conditions, and goes forward with the application of bioprocess engineering principles to guarantee a successful upscaling.

The downstream processing is often an intricated combination of microbial physiology, chemistry and physics to fine-tune a process very often developed by empirical trials performed at the Pilot scale. The choice of a suitable protective compound to preserve the physiochemical properties of the product before the drying process, and the final formulation with excipients are crucial steps that might put the yield of the entire process at high risk of failure.

Moreover, the manufacturing of probiotics quite often requires retrofitting of existing plants and equipment designed to meet specifications for the food industry, and a good dose of creativity is needed to meet ever-changing regulatory requirements.

Science and technology provide many solutions to support all phases of development but only an open-minded, multidisciplinary approach can select the right tools that are necessary to guarantee a viable and successful industrial production.